Early Glass Making In East Cambridge

by Doris Hayes-Cavanaugh, 1926

Much has been said recently about the business growth of Cambridge, and a number of publications have stressed the fact that Cambridge, and particularly the section known as East Cambridge, now stands very high in the scale of New England manufacturing centres. Imposing schedules of plants and factories have appeared, setting forth large capitalizations and startling production-figures, but none of them even vaguely refers to the fact that there was in East Cambridge, more than one hundred years ago, a factory whose products were sent all over the world, whose methods revolutionized a great industry, and whose yearly business grew to half a million dollars. This was the New England Glass Company, formed in 1818, and continuing in business in East Cambridge until 1888, when the discovery that natural gas could be used most inexpensively in glass making, added to the threat of a glass-workers’ strike, caused the business to be moved to Ohio.

Although the search for “early glass” is one of the more recent phases of present-day antique collecting, 1817 is not a very early date in the history of American glass making. The first trace of glass making in America is found in Jamestown, Virginia, in 1608, when the English colonists under Captain Christopher Newport gave the first impetus to this very decorative craft. Shortly after, a second essay at glass making was carried out under Captain John Smith. He built a second glass house in 1621, which was at work until 1625. A few beads of lovely colorings which were made at that time are still to be seen in the Pennsylvania Museum and School of Industrial Arts. They were evidently made up for trading with the Indians, but unfortunately history does not state whether Pocahontas led the fashion by wearing them or not.

In 1638 or 1639, window glass, bull’s eyes, rude bottles and other glass necessities were made at Salem, Massachusetts, but this venture lived only three or four years. In 1654-1656 we hear of two Dutch glass-makers, Jan Smeedes and Evert Duyckingk, but none of their actual work remains. By 1683, an English glass-maker, Joshua Tittery from Newcastle on Tyne, operated a glass house, and in 1787 a member of the Pennypacker family founded a glass house which continued for four or five years. New York boasted two factories in 1732, and Caspar Wistar started his New Jersey factory in 1729, a notable date in the history of American glass making. He brought over artisans from Holland to teach “his son and himself, and no one else” the secrets of glass-making. He produced the first flint glass, his green color being in great favor, and his dark blue, a much scarcer color, being of exceptionally good quality.

“Baron” Heinrich Stiegel, that picturesque and now almost legendary figure of early American glass making, started his glass works in Lancaster County, Pennsylvania. This young German had come from near Cologne to America in 1750, and soon became a prominent landowner and ironmaster. By 1765 he had a splendid glass factory and was making what is now the greatly sought-for and most valuable American glass. The wonderful colors are much copied even today, and his engraved glass is remarkable for its color and brilliancy. The patterns, although crude, are always graceful. But the painted glass with its brilliant reds, blues, yellows and whites was made under the “Baron’s” personal supervision, and extraordinary results were achieved. The designs were typically German. The meteoric business career of Stiegel was suddenly ended by debt in 1774, and the glass making came to an end at the same time.

To these two men, Caspar Wistar and Heinrich Stiegel, the colonists owed much, for the beautiful glass which they made was one of the first channels through which beauty came into the homes of our country. Stiegel and Wistar glass has been found in out-of-the-way parts of South and West Jersey, all through the Middle Atlantic States and New England. Much of the Stiegel glass was sent to Boston. The best permanent exhibits of the work of these early makers are to be found in the Pennsylvania Museum and School of Industrial Art in Philadelphia and in the Metropolitan Museum in New York.

In New England also several glass plants were started quite early. In 1639 a plant was started in Salem which prospered considerably in the making of glass bottles. No specimens of the work are known to exist, but fragments of glass still to be found on the site of the factory prove it to have been a very crude sort. In what is now a part of Quincy, a group of German workmen started a glass works which had a varied line of products, including lamps. The spiral twist was the distinguishing feature of their designs, but the quality of the glass was not good. Robert Hewes began to manufacture glass lamps and a general line of glass ware in Temple, New Hampshire, in 1780. All the lamps made at this plant were made to use patented burners, in which the wick came through a perforated cork instead of through pewter or brass caps as formerly. A company was established at Chelmsford in 1820 for the manufacture of window glass. About three hundred and thirty feet of window glass annually was made here, and much of it sold by the agent of the New England Glass Company in Boston.

In 1787 a glass factory was started in Boston on Essex Street by Whalley and Hunnewell. They later took into the firm a German named Lint, were given a bounty by the state, and prospered. From 1822 the business was known as the Boston Window Glass Company. A larger factory was erected in South Boston in 1811, but blowers were very hard to get, on account of the War of 1812, in spite of sending to England for them. Flint glass workers who had come from England earlier were finally secured. The South Boston plant failed several times, but started up again each tune and was still running in 1854. Several of the workmen from this plant later went to the Boston and Sandwich Glass Company. I have an original bill of “The Glass-House Essex Street” dated Boston, February 13, 1798, on which one Mr. Moses Billings is charged $12.67 for 100 lights of glass, seven by nine niches in size, which quite nearly approximates the present price. The product of this factory was so highly thought of that it set the standard of quality for many years. A picture of the South Boston plant shows that it was decidedly sizable for the times.

In 1811, the Porcelain and Glass Manufacturing Company was formed, and built a factory at East Cambridge. I have a newspaper clipping from the Columbian Centinel of February 24, 1816, reminding the stockholders of the Boston Porcelain and Glass Manufacturing Company of the annual meeting, which is signed by Thomas Jackson, clerk of the corporation. With it is a receipt for a sixty dollar assessment on six shares of stock in the company, signed by Robert Sugden. This receipt is dated in Cambridge on the first of April, 1817, and must have been given at the beginning of the financial trouble of the company; because before 1817 had drawn to a close, the company and the plant were sold at auction. A new company bought it, and it was renamed the New England Glass Company. The company had an initial capital of $40,000, employed forty hands, and ran one six-pot furnace with 700 pounds to each pot.

There were four men concerned in the forming of this new company: Amos Binney, Edmund Munroe, Daniel Hastings and Deming Jarves. The company was incorporated by the state of Massachusetts, and when I hunted up the act of incorporation in the Massachusetts archives, I found that the actual signers were Amos Binney and Edmund Munroe. Of these four men, two have a great interest for us, and in summing up the available information it seems to me that they had more to do with the actual building of the business than the others. They were Edmund Munroe and Deming Jarves.

Edmund Munroe was born in Lexington, a member of the historic family so long associated in our minds with the Munroe Tavern and the Lexington fight. As a young man he started in the banking business, and his rise was very rapid. He early went out to Munroe Falls in Ohio and established a bank there which was highly successful. On returning to Boston, he went into the textile field and into shipping. His cousin was the head of the great Paris banking house of Munroe and Company, and through him Edmund Munroe soon had world-wide business contacts. His ships brought cargoes of merchandise from many ports, and he was one of the first to see the possibilities for America in the export trade. Edmund Munroe married three times, and through his third wife, Miss Sewall of the famous Maine maritime family, he greatly strengthened his shipping connections. A portrait of him shows many of the qualities which made him successful in business when foreign trade was even more of a gamble than it is today. His eyes are keen but humorous, and his high, thoughtful forehead and firmly cut mouth give evidence of the sort of “backbone” and perseverance that New England business of those days was built on.

Deming Jarves on the other hand was a practical glass maker. He was a man of considerable education who had made a deep study of glass making from earliest times. Later, after he had founded the Sandwich works, he wrote a little book of his formulae and receipts for glass making. Selections from it have recently been published in the Transcript and in Antiques magazine. It covers a good bit of glass history, even going back to Phoenician glass. One point which he made interested me. In Venice, glass making was considered an art rather than a craft or trade, and apprentices of that day were selected with meticulous care. Jarves quotes one case in Venice where a lady of the nobility (I think it was the Doge’s daughter) was married amid great pomp and festivity to “a gentleman glass-maker.”

Jarves was a voter here in Cambridge in 1822, a selectman in 1823-24, and representative to the General Court in 1828. He was the agent for the New England Glass Company — sales-manager, we should call him today; and while Munroe arranged for the capital and credit for the new concern, Jarves found the markets and had much to do with the manufacturing end of the business. In looking up this family, I found three Deming Jarveses: the elder, who was in the dry goods business; the second, of whom we have just been speaking; and Deming Jarves III, who made his home in Paris and was of much help to Americans in the late war. He died, I believe, about three years ago.

The following is a quotation from an article about the New England Glass Works taken from Gleason’s Pictorial and Drawing Room Companion, a weekly newspaper of the mid-century, which, although it was not quite so fashionable as Godey’s Lady’s Book, was very widely read: “There is hardly a home from Maine to Louisiana which has not more or less of this excellent ware in domestic use. Every description of glassware, from a simple pressed glass wine glass to the most elaborately cut and richly plated, gilded, silvered and engraved glass is produced in a style of beauty and excellence unrivalled in the world.” The article then goes on to invite the reader to visit the plant, and he is informed that it is the oldest establishment of the kind but one, and the largest in the world. This was in 1851. About 450 workmen were then employed, there were some thirteen buildings, and the capital stock of the company was $400,000, on which a semi-annual dividend was paid. Two years later the capital was increased to half a million, there were five furnaces with ten pots of 2,000 pounds each, and 500 hands, and the annual business amounted to $500,000. The earnings of the company afforded a large percentage of profit, and its shares were never to be found in the market!

This article goes on to speak of the chimney at the New England factory: “It looms up loftily [what a talent for alliteration those Victorian reporters had!] to the eye that regards this part of Cambridge from a distance — it is 230 feet high — actually ten feet higher than Bunker Hill Monument!” This chimney was connected by underground tubes to the smallest as well as the largest furnaces, so that the smoke and gases were carried off into the air at a great height. Speaking of this chimney, it amused me very much a year or so ago, when I was trying to find out something about the kinds of glass that were made at the New England plant, to find, on asking several people whose families had dwelt for generations in Cambridge, that not one of them could tell me what kind of glass was made there, although all in their youth had been taken to the factory to watch the fascinating process of glass-blowing. But each separate individual told me that the chimney was ten feet higher than Bunker Hill Monument!

The New England Glass Company’s warerooms in Boston were in the old Sun Tavern on Batterymarch Street. Later, Mr. Richard Briggs was the selling agent in Boston; and many of you who remember the quality of his lovely glass and china will realize that New England glass must have appealed to a fine clientele or Mr. Briggs would not have stocked it. The very fact that Mr. Briggs was the agent is one of the strongest arguments that I can imagine against the theory that New England glass was made up to be peddled around the country on the itinerant tin peddler’s cart, as we are sure Sandwich glass was. Nor was New England ever made for advertising premiums, as Sandwich was. These two tiny catalogs of Richard Briggs show that people were much more willing to buy on faith than they are today, for the only picture in them is of a new style student’s lamp.

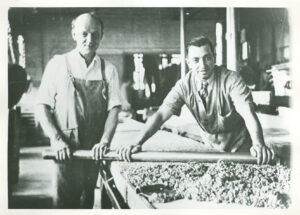

The life of a glass-maker in those days was a hard one, for the excessive heat under which the glass was melted, the gases which he drew into his lungs, and the tremendous pressure which was necessary in the physical process of blowing the glass made the mortality percentage in his craft very high. In 1827 the pressing mould for glass was invented by a workman named Robinson at the New England factory; though the invention was taken up at once and much more extensively used at the Sandwich factory. This mould revolutionized glass making, and also made it possible for a glass-maker to live out his allotted span of years. An infinite variety of glass could now be made with a great saving of time and money. That this humanitarian and labor-saving device, which completely altered a great industry, was, like the sewing machine, invented in Cambridge, is a fact that is not as well known as it should be.

A short while ago I had the good fortune to be taken over the glass works of the Pairpont Manufacturing Company at New Bedford, which was formerly the Mount Washington Glass Company. Of the many Massachusetts glass factories once in operation, this is the only one left that is still making glass in the way that they did at the New England. Perhaps I should except the Union Glass Works at Somerville, but that plant was shut down a few months ago, and I have not heard that they have started up again.

The process of making glass is a very intricate one and requires a highly skilled worker. Glass making seems to run in families, for many of the men I met there represented the third generation of the families who had made glass at Pairpont. The glass furnaces are built of brick and cement, and are cylindrical in shape, the proportions being not unlike those of a modern gas house, though necessarily much smaller. Conical shaped openings called “glory holes” hold the fire pots, and in the old days glass was slowly annealed on the brick shelves above the fire pot. The glass is melted in large pots and crucibles; the “gaffers,” as the glass workers are called, dip their long iron tubes into the red-hot liquid mass, take out a portion and, revolving it continuously on the tube, which is about four feet long, roll it on a polished iron plate to give it an even surface. Then the blower commences. He is usually a husky, sturdy man who blows out his cheeks until he looks like Old King Cole, while the ball (or bubble to be more exact) of glass swells like a soap bubble. Then a second “gaffer” slips it off on another iron rod which has been heated red hot. A pair of pincers is wetted in water and applied to the neck, which is immediately severed and drops off into a bucket of water.

When a piece of moulded glass is being made, the hinged iron mould is slipped around the red hot bubble and the blower takes it again. As he blows, the hot molten glass fills the surfaces of the mould. Then the mould is taken off and the blower’s tube, or “pontil,” is deftly broken away from the bottom of the piece. The resulting little roughness, or “pontil mark,” is characteristic of the earlier moulded glass. On the later pieces of poured or moulded glass the bottoms are smoothly finished, with no trace of pontil mark roughness, as the tube is not used.

The piece is then set on the shelf of a cooler oven to harden. Today this process takes about five days; the quality and resistance to chipping of fine glass is due to this slow, careful cooling and hardening.

The plant, of course, started by making blown flint glass — that is, glass in which silica is the main ingredient. Silica was made in England from calcined and pulverized flints. Oxide of lead was also added to make the glass refractive and brilliant, and, contrary to previous theories, this glass is remarkably clear and sparkling in spite of the lack of barytes. This pair of decanters is a splendid sample of the earlier type. The etching is very simple and the whole product quite a bit more attractive than the later moulded kind.

The “Bohemian glass” made at East Cambridge is likely to have an orange tinge which quite definitely differentiates it from the foreign variety, but collectors are just beginning to realize that much glass of lovely coloring heretofore supposed to be Bohemian was made at the New England plant. A well-known antique dealer who has specialized on old Bohemian glass among other things for some time told me that in his opinion fully seventy per cent of the glass sold today as antique Bohemian was made at the New England glass works in East Cambridge — and I really feel that he ought to know!

New England glass was sold all over the settled parts of the United States very early, and, as I have said before, was exported through the efforts of Edmund Munroe. He never had time to travel much himself because he had so many irons in the fire. He had great cargoes of elegant foreign merchandise, including Irish, English, French and Bohemian glass, which was sent to his glass works to be copied. Much of the moulded glass which we know to have been made at the New England shows the patterns copied and adapted from Waterford and Stourbridge. The later patterns made at Sandwich show the same influences also, as was very natural. This sugar bowl and creamer, although the shapes are frankly reminiscent of the silver “helmet” pitchers made by Cony, Revere, and others, have an unmistakable air of having been copied from the Stourbridge patterns in cutting. It is interesting to note the variation in color between these two goblets which were both made at the New England; one is crystal clear with the much-desired silvery light which is supposed to be the supreme test of “Old Sandwich,” while the other has a dull lustreless color which is probably responsible for the remark heard so often that New England glass has neither sparkle nor life.

To go back to Deming Jarves — he stayed only seven years at the New England plant, for in 1825 he went to Sandwich on Cape Cod and founded the Boston and Sandwich Glass Company. Edmund Munroe and several other directors of the New England were directors of the Sandwich — which rather gives color to a theory which I heard the other day that Sandwich was founded to make so-called “kitchen glass” and protect the New England business from the cheaper competition. At first Sandwich had only one eight-pot furnace, each pot holding 800 pounds, compared with the five ten-pot furnaces at the New England, and employed but sixty hands, with a yearly product of $75,000. By 1853, however, the capital was $400,000 and there were five hundred hands, with weekly “melts ” of 100,000 pounds, and nearly $600,000 worth of glass was put out annually.

The formulae which Jarves used at Sandwich contained barytes, which he had not used at the New England. To this is laid the credit for the silvery sparkle which is often to be found in the “lace” or “snake-skin” and stippled glass patterns of early Sandwich. But the later Sandwich glass, which was made up in a great quantity to be used as advertising premiums, was very heavy and uninteresting, lacking to a noticeable degree the very qualities which makes early Sandwich so much admired at present. The yellow or “canary” color was brought to the Sandwich factory by an English workman from Bristol; but the process added so much to the cost of the glass that a much smaller quantity was made. Candlesticks, lamps, scent bottles and vases were made in this color, which must not be confused with the Victorian yellow glass which was made later in such quantity. These two sauce dishes I know to have been made at the Sandwich plant, and, as you see, they are very clear and silvery. They were traded for by an elderly relative of mine who lived in Antrim, New Hampshire, from 1860 to 1870. She traded her soup bones and soap grease with an itinerant tin peddler for them. In this connection I cannot but think of Mary E. Wilkins’ hero in An Humble Romance. He, you remember, was an itinerant tin peddler and had his wagon filled with tin ware; brooms were tied on the side; and I am sure he must have had Sandwich glass in the box under the seat. Sandwich was distributed in this way all over New England (that is why one finds pieces in such out-of-the-way places); but after consulting every available authority I cannot find any reason to think that New England glass ever was.

Deming Jarves was the first agent of the Boston and Sandwich Glass Company and Sewall H. Fessenden his successor. Jarves’s business card reads this way: “Plain moulded and cut flint glass ware in all its varieties, also all kinds of Apothecaries, Chemical and Philosophical Glass-Ware.” (Philosophical glass was that used for apparatus in physics, which was then known as “natural philosophy.”) On Fessenden’s card we still have all sorts of glassware, including the philosophical, but brass chandeliers, japanned ware, Britannia and plate castors, patent ice pitchers, spoons, toilet sets and spittoons had been added to the stock.

“Cup plates” were first made at Sandwich, but this was not known when pressed and moulded glass was first collected about twenty-five years ago. I think that the impression is current that Sandwich glass collecting is a vogue of the past five years; but Mr. George Francis Dow, the well-known antiquarian, told me that he arranged an exhibition of cup plates at the Essex Institute nearly twenty years ago. He remembers when the late Edwin A. Barber of the Pennsylvania Museum of Industrial Art came here. He then bought cup plates for ten cents each. At that time it was believed that cup plates were made in England. Sets of china dishes used to come with the china cup plates to match, but the pressed glass ones became so popular because they were made in patriotic and historic American designs.

Barber wrote the first book on American glassware. It was a tiny volume, published in 1900, but it is still the authority as far as it goes. It, however, does not mention either the New England or the Sandwich plants, although it is generally thought that Barber was responsible for the revival of Sandwich a bit later. He says that “cup plates were pressed in metal moulds by means of a plunger — it is believed that they were made in England and we have no knowledge that pressed glass designs were produced so early in this country.” Perhaps I am a bit prejudiced, but it hardly seems logical to me that even a shrewd British manufacturer could have brought himself to make cup plates resplendent with the American eagle, Bunker Hill, the thirteen stars, and allusions to the defeat of the English in America so soon after the war of 1812. But this evidently did not occur to Mr. Barber. Of course, we now know that these pressed glass plates were all made at Sandwich, and, judging by present prices, they will soon be invaluable.

For the past five years all the moulded glass I have seen in antique shops has been without a doubt “Early Sandwich”; and I think it is not much of an exaggeration to say that tons of moulded glass have been sold as Sandwich. That taunt, so familiar to all collectors of glass, “Is it Woolworth period?” really has a foundation of fact; for in the early days of the Woolworth stores Sandwich glass was sold in them, although perhaps not to the wide degree that it is today.

While we are still speaking of Sandwich glass, I have here something which gives a vivid picture of Jarves’s high ideals of glass making. It is the certificate of a regularly indentured apprentice (a “gaffer’s sheepskin,” so to speak), and it tells that one Edward Talbot is a regular indentured apprentice of the B. & S. Glass Co., having served through his apprenticeship with fidelity to the company and correct deportment to the superintendent of the factory. Then there is a menu of a dinner for the directors of the Sandwich plant, given at Boston’s fashionable hotel, the Revere House. It lists all the good things which they had to eat, and then concludes in conspicuous capitals with the phrase, ORNAMENTS AND FLOWERS!

Now think for a minute of the two plants: one started in 1818 and ran until 1888 — seventy years of production on a large scale with a nation-wide distribution; the other started in 1825 and was in business until about 1888. Though it grew rapidly it never attained the prestige, volume or quality of the older factory. It made some colored glass, as recent prices for canary-colored dolphin candlesticks will eloquently testify, but nothing to compare with the engraved, cut and silvered products from East Cambridge.

In the Columbian Centinel of October 12, 1825, the advertisements of the two firms are found side by side. New England advertises its own — South Boston, Crown and Chelmsford window glass, entry lamps, the fashionable new astral lamps, and sconces with cut glass founts. Jarves, however, being but just started, is appealing for orders for any article to be made in flint glass. You will note that this is under his own name, evidently before the formation of the “B. & S.” Glass Company.

The New England Glass Company flourished in East Cambridge until the eighteen seventies, when the business slumped; but a “gaffer” from England who had had much experience in colored glass came to the factory and business picked up again. This green glass pitcher is a sample of the work done at that time. This square brown dish is a “horrible example” of the earlier work, and as you look at it, you will not wonder that such glass was harder to sell than some of our earlier exhibits. This purple vase is a very rare color for New England but it was loaned to us by a lady whose father bought it at the factory.

Strange as it may seem, there is almost no printed information anywhere on New England glass, except these clippings from Gleason’s Pictorial. Until about a month ago, I never heard of New England glass. Mr. Arthur Hayward of the Transcript, in his book on Colonial Lighting, has about four pages on it. He shows a rare handbill of the works in the eighties, when the Munroe family had sold out their interests to Mr. W. L. Libbey, who had long been employed there. It advertises particularly the lamps and railroad lanterns. This rather large whale oil lamp is of very pleasing design but the glass shows a distinctly bluish color. Mrs. N. Hudson Moore in her new book on Glass, American and European, notes that Deming Jarves while at the New England plant invented the glass furnace, but she does not state that the real power behind the factory was Edmund Munroe, who financed the enterprise and made it possible. His descendants recall the interest of the family in the Sandwich plant also; so that it is not at all unlikely that the far-seeing Edmund Munroe, sensing the call for moulded glass among the people who could not afford cut glass, encouraged Mr. Jarves to found the new plant for this reason.

I should like to emphasize one statement that Mr. Hayward makes in Colonial Lighting, namely, that no one can tell the difference between New England glass and Sandwich, although Sandwich is reputed to have a better color. There are enough authentic pieces of New England glass owned in Cambridge (they were recently shown at an exhibition held by the Cambridge Historical Society) to quite disprove the contention that all New England glass is dull and heavy looking. But the patterns made by the two companies were very similar — particularly lamps — and often identical, as was perfectly natural when one realizes that the same group of men had the running of both factories for quite a long period. When the New England Glass Company was sold and moved to Ohio in 1888, the new owner was Mr. Libbey, who had long been employed at the plant. He stressed the new cut glass which was just coming into vogue, and his product later became internationally famous for its beauty and fine quality as “Libbey cut glass.”

The only manufacturing glass works now remaining in Cambridge is that of P. J. McElroy on Second Street, and that makes bottles — not the collectible, and ofttimes fragrant type of bottles which, I am told, bring back joyous memories. These are pharmaceutical and apothecaries’ bottles; they have only this in common with the other type — they, too, are now filled by prescription only.

This article can be found in the Proceedings of the Cambridge Historical Society Volume 19, from the year 1926.